loading

Home aluminum profiles are loading by hand. it takes about five hours to load a 40HQ container in full.

counting

Home aluminum profiles are picked and counting before loading

warehousing

Home aluminum profiles are packed and stored in warehouse ready for loading and shipping

quality control

Home

packing

Home protective film is made when profiles coming through the machine. heat shrink film is packed by hand, then to make it tight through the machine.

wood grain

Home packing with wooden texture paper and ready for heat transfer. wood grain vaccum machine will transfer the wooden texture from paper to aluminum profile surface in stove at high temperature.

powder coating

Home powder coating thickness is 40-120um, which is durable for different weather condition.https://www.intop-alu.com/wp-content/uploads/2023/05/video_1714028485.mp4 we not only have horizontal coating lines, but also have vertical coating lines powder coating colors are various for customer choices

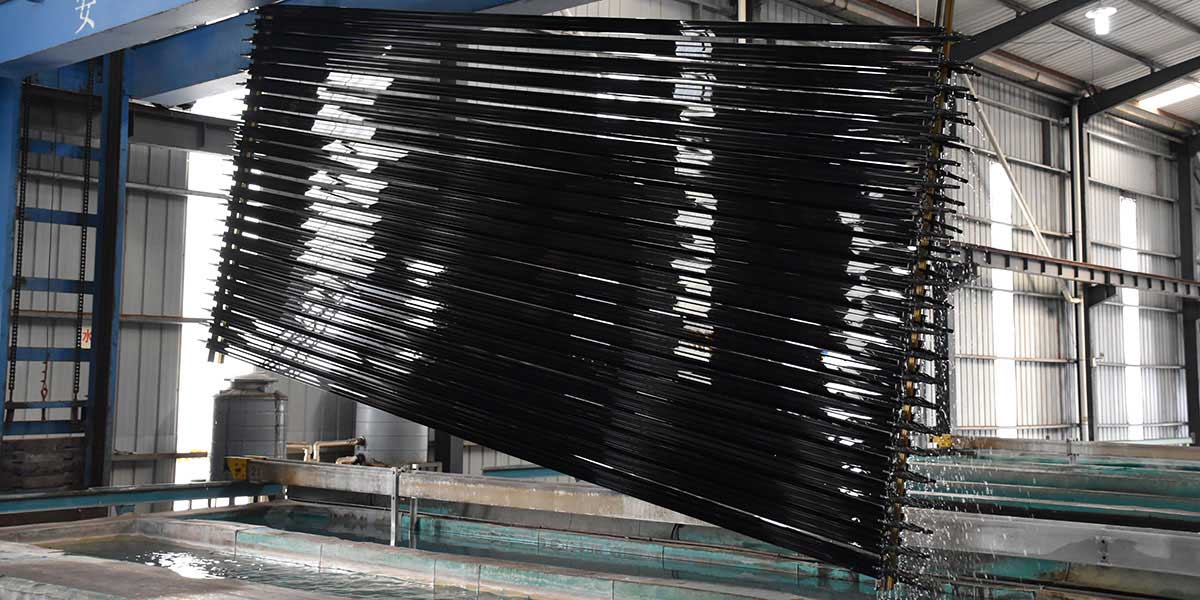

anodizing

Home anodizing is the main surface treatment for aluminum profiles, national standard coating thickness is AA10https://www.intop-alu.com/wp-content/uploads/2023/05/VID_20240516_105330-1.mp4 coloring is made like champagne, bronze, black by sinking the aluminum profiles in tanks for minutes. sealing and drying is also important for lifetime, then for packaging

polishing

Home polishing can remove the extrusion lines and get a bright mirror surface by mechanical forces some profiles for bathroom need chemical polishing after this processment

sand blasting

Home sand blasting will create matt surface and eliminate the extrusion lineshttps://www.intop-alu.com/wp-content/uploads/2023/05/video_1714029532.mp4 sand blasting is a pre-treatment before anodizing or powder coating